In an engine, carbon deposits typically accumulate in several key areas:

- Valves and Valve Seats: Due to oil and impurities in the intake air, valves and valve seats are major areas for carbon build-up.

- Intake Manifold: Impurities during the intake process can also lead to carbon deposits in the intake manifold.

- Fuel Injectors: Incomplete combustion can cause carbon accumulation on fuel injectors.

- Pistons and Piston Rings: Aging or incomplete sealing of pistons and piston rings can also result in carbon build-up.

- Cylinder Walls: Residues from combustion can deposit on the cylinder walls, forming carbon deposits.

These carbon deposits can affect engine performance and efficiency. Therefore, regular cleaning of engine carbon is crucial.

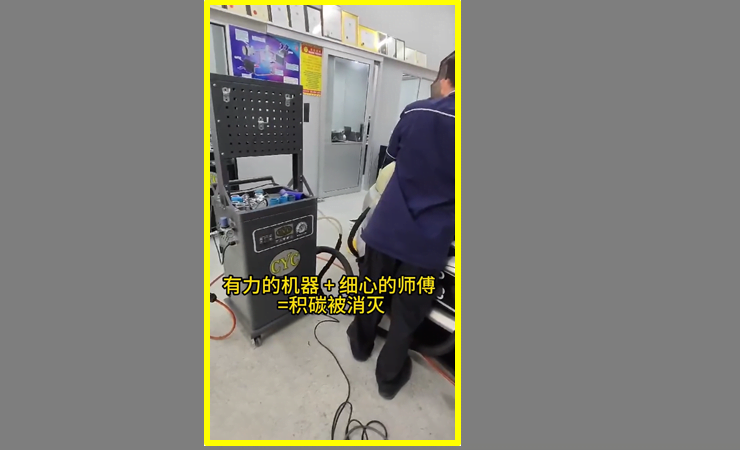

Today, we are sharing a method for cleaning internal combustion engines— WALNUT DECARBONIZE CLEANING Method. We use a AUTOMOTIVE WALNUT BLASTER DE-CARBON MACHINE.

WALNUT DECARBONIZE CLEANING Process:

WALNUT DECARBONIZE CLEANING for engine valves involves using finely crushed walnut shells to clean internal engine components. The process includes the following steps:

- Preparation: Ensure the engine is in an appropriate working state and has cooled to a safe temperature. Then, remove relevant components to access the valve area.

- Walnut Shell Injection: Use specialized equipment to inject walnut shells into the engine’s intake system. The shells are carried by the intake airflow to the valves and valve seats, helping to remove carbon and dirt.

- Cleaning and Residue Removal: Continue spraying walnut shells to ensure thorough cleaning. After cleaning, remove the walnut shell fragments from the engine, typically using a vacuum or other methods.

- Reassembly: Reinstall all components and ensure everything is functioning properly.

WALNUT DECARBONIZE CLEANING can help restore engine performance and fuel economy, reduce exhaust emissions, and extend engine life. However, it is important to note that this method may not be suitable for all types of engines.